Free & Easy Returns

Best Deals

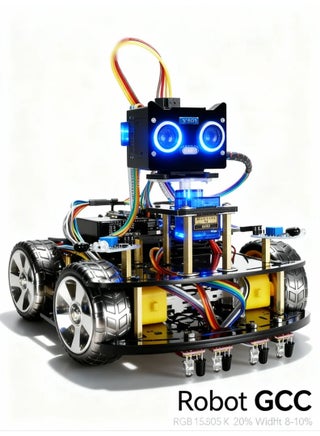

This Smart Educational Robot Car Kit redefines hands-on STEM learning by merging mechanical engineering, sensor logic, and coding into one integrated platform.

Students learn not by watching, but by building, wiring, coding, and experimenting—gaining a real-world understanding of how modern robotics systems operate.

Built on the Arduino open-source ecosystem, the robot supports a wide range of intelligent sensors, including ultrasonic obstacle detection, infrared line tracking, Bluetooth communication, and gyro balancing.

With block-based programming (Blockly) or Arduino IDE, learners can create logical algorithms that allow the robot to navigate autonomously, avoid obstacles, and react dynamically to its surroundings.

Each module uses a plug-and-play connector system, eliminating soldering and making upgrades simple for classrooms and hobby labs alike.

The Mecanum wheel drive delivers full omnidirectional motion—forward, backward, sideways, and diagonal—providing an ideal model for exploring motion vectors and physics-based control concepts.

Students can combine the infrared and ultrasonic systems to simulate AI decision-making: the robot senses, analyzes, and adapts, just like real autonomous machines.

All major parts are made from durable aluminum and eco-friendly ABS plastic, ensuring long-lasting use for repeated class sessions or robotics competitions.

Comprehensive manuals, tutorial videos, and open-source example codes guide users from wiring basics to logic design and advanced control experiments.

This kit is not only a tool for programming education, but a gateway to understanding artificial intelligence, automation, and robotics principles.

Perfect for schools, makerspaces, and home labs, it encourages creativity, teamwork, and innovation — inspiring the next generation of engineers and inventors.